Fiber laser with adjustable pulse duration enables new ablation processes P2 and P3 in the production of CIGS photovoltaic modules

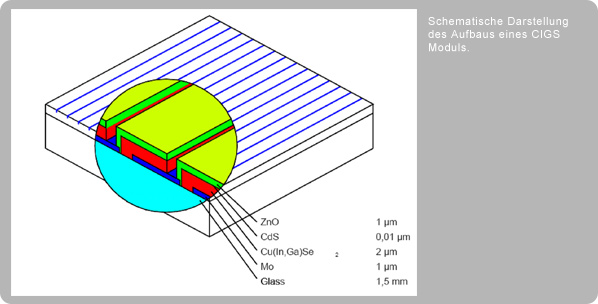

When producing thin-film photovoltaic modules, alternating coating processes and ablation processes, in this case the writing of lines, are carried out on a glass plate. This is how the individual solar cells are created with the two electrodes at the top and bottom and the photovoltaic layer in the middle as shown below. CIGS cells are typically built on a Mo electrode layer. In three ablation steps P1, P2 and P2, the Mo layer is removed onto the glass (P1), the CIGS layer is removed onto the Mo (P2) and the transparent electrode layer is removed using the CIGS onto the Mo (P3). So far, P1 has typically been done with ns laser pulses, while P2 and P3 are achieved by mechanical scratching with needles. Since the needles wear out quickly, various laser processes are currently being investigated for their suitability for P2 and P3.

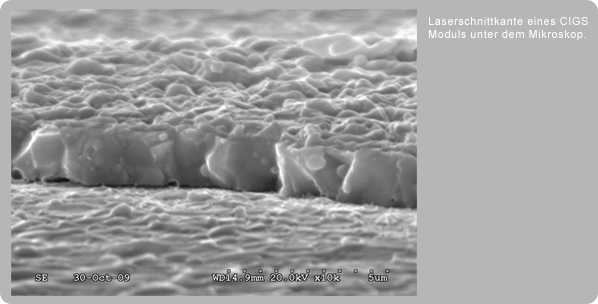

A new fiber laser from ESI-Pyrophotonics can be programmably adjusted in terms of pulse duration and pulse shape in the range of 2-250 ns with a resolution of 1 ns. Studies on CIGS modules at Pyrophotonics, NRC Canada and the National Center for Photovoltaics* have shown that 1064 nm pulses with a well-defined pulse duration of 5-10 ns produce reliable P2 and P3 cuts, without thermal melting, which leads to disruptive short circuits. or build-ups in melting zones.

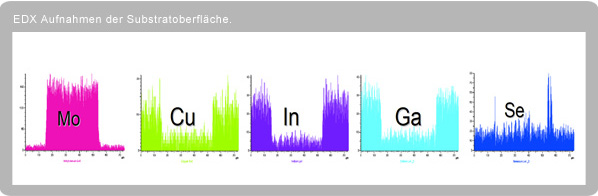

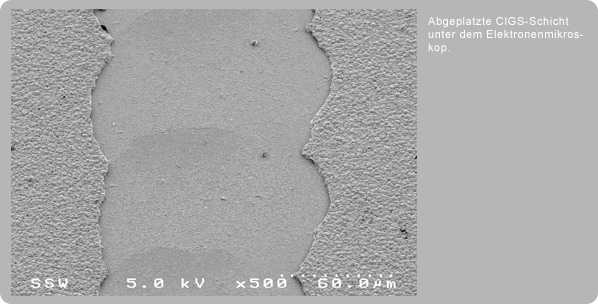

The underlying process here is less an ablation than a laser-induced removal of the CIGS layer. The laser light at 1064 nm penetrates the CIGS layer, is absorbed at the Mo interface and the resulting gas pressure caused by Se gas causes the CIGS layer to flake off. This creates a fracture edge without melting, as can be seen in the electron microscope images above.

EDX images showed that only minimal residues of Cu, In and Ga remain at the bottom of the track, while Se is present everywhere, supporting the proposed removal mechanism. If the pulse duration is chosen correctly, the process window in terms of energy density and depth of focus is large enough to ensure a stable industrial process.